Win-win recycling

Can recycled materials be cost-efficiently processed and turned into high-quality products in a way that also protects the environment? ESE GmbH provides the answer to this question at its plant in Neuruppin, where well over two million waste containers and recyclables containers are produced through injection moulding from plastics every year. The manufacturer consistently focuses on sustainability and on saving energy and resources.

ESE GmbH – how recycling saves energy and resources

Can recycled materials be cost-efficiently processed and turned into high-quality products in a way that also protects the environment? ESE GmbH provides the answer to this question at its plant in Neuruppin, where well over two million waste containers and recyclables containers are produced through injection moulding from plastics every year. The manufacturer consistently focuses on sustainability and on saving energy and resources.

Sustainability is in demand

An increasing number of municipalities and entire states are adopting climate protection programmes with the aim of becoming climate neutral in a few years’ time. Copenhagen was the first to do so, but Costa Rica and Berlin also aim high with their ambitious goals. In order to achieve these goals, a transition towards renewable energy sources is not enough; even everyday consumer goods procured by municipalities must meet increasingly high standards in terms of environmental compatibility.

How can a recyclables container become more environmentally friendly?

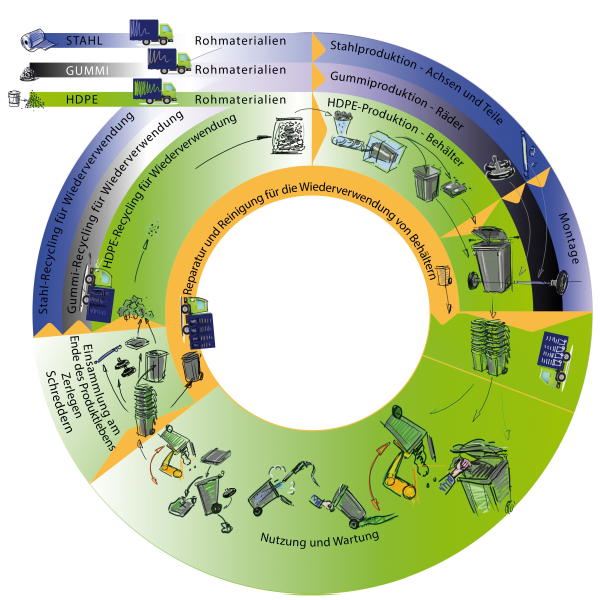

At ESE the product design itself creates the basic conditions for functional products that simultaneously meet the requirements of sustainability and environmental friendliness. The products must make sustainable, resource-efficient production processes feasible and they have to be recyclable to the largest possible extent. Optimising the transport of the products can also have a positive influence on the carbon footprint of the containers. The containers’ high quality also leads to a longer useful life, so that they have to be replaced less frequently.

Jens Wunderlich, Managing Director of ESE GmbH, explains that ESE’s commitment to sustainability has a decisive impact on the entire production of waste containers and recyclables containers. “It ranges from energy and environmental management certificates for the plastics plant in Neuruppin to the use of green electricity of up to 100%. The ‘zero waste’ concept ensures that any waste generated during the production processes is immediately reintegrated into those very same processes and reutilised. Furthermore, we have continuously optimised our processes and invested in modern machinery and tools,” he says, “This has enabled ESE GmbH, for instance, to achieve a significant reduction of its energy and water consumption in recent years.”

Materials in a loop

The predominant material used for the production of the containers is the plastic HDPE, a polyolefin, which is derived from crude oil. During its search for more environmentally friendly alternatives, ESE became a pioneer back in the 1980s in researching the use of recycled materials and in making them increasingly suitable for the production of plastic containers. Today, ESE has completely closed the loop when it comes to their plastic containers. The containers can now be made exclusively out of recycled materials and are fully recyclable at the end of their useful life.

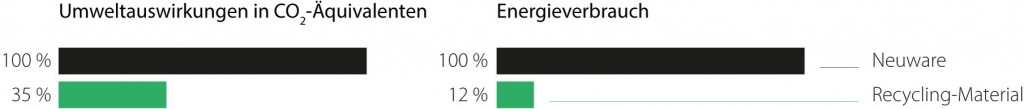

It has been shown that recycled HDPE is much more sustainable than newly produced products made out of HDPE. The ecological footprint of the material shows that its production out of recycled plastic saves approximately 65% of carbon dioxide equivalents and that it also saves approximately 88% of the energy that is needed for the production of new products. In addition, the use of recycled materials saves up to 100% crude oil. It is highly doubtful whether crude oil — and thus raw materials such as HDPE — will continue to be readily available because many emerging countries have not reached their peak in terms of resource consumption.

In order to make the use of this much more environmentally friendly recycled plastic future-proof, the plastics specialists in ESE’s development team are conducting continuous further research and development.

ESE has accumulated a lot of expertise and experience over many years. The company is now able to produce plastic containers from recycled materials at the same high quality as newly produced ones. The production of the containers is subject to continuous internal and external quality control processes; the containers are tested in accordance with the applicable European standards and they are certified based on the strict requirements of the RAL quality mark. Each container must comply with the strict guidelines, regardless of whether it is made of recycled materials or is newly produced.